Soft Starter: Working Principle, Applications, Features and Types Explained

There are multiple ways to start the motor used in the machines and pieces of equipment. Even though a typical startup gets the job done, it is far from ideal in many aspects. Soft Starters are widely used to make sure the motors can be safely started preventing grave damage. In this blog, we have explained in detail what a soft starter is, its functions, Applications, and more. If you’re looking to buy soft starters for your business applications, feel free to reach us.

Table of Contents

- What is a Motor Starter?

- What is a Soft Starter?

- Soft Starter Working Principle

- Applications of Soft Starters for Motors

- Motor Soft Starters Advantages

- ABB Soft Starters

- Features of ABB Soft Starters

What is a Motor Starter?

A motor starter is an electrical device used to safely start and stop a motor. The motor starter, like a relay, switches the power ON/OFF, but unlike a relay, it protects the motor against overcurrent and low voltage.

The extensive use of induction motors in multiple industrial applications calls for the need for a motor starter.

What is a Soft Starter?

The soft starter is a type of motor starter that is used to reduce the load and torque of the motor during its start-up. This function is done to reduce mechanical and electrodynamic stress on motors while extending their lifespan.

Soft starters ensure a gradual increase in the voltage during the motor starting. By doing so, it allows the motor to slowly accelerate and gain speed gradually. This mechanism stops the sudden supply of voltage while protecting the motor from mechanical damage.

The motor starting is controlled using the supply voltage. This is because the current depends on the supply voltage and this current is directly proportional to the torque of an induction motor.

Applying full voltage while starting a normal motor starter can generate maximum starting torque which can potentially cause mechanical damage to the motor.

As a result, a soft starter minimizes starting torque and gradually increases it in a safe manner until it reaches the rated speed. Upon reaching its rated speed, the soft starter restores full voltage to it.

The supplied voltage is gradually dropped during motor halting to slow the motor smoothly. When the speed approaches zero, the input power supply to the motor is cut off.

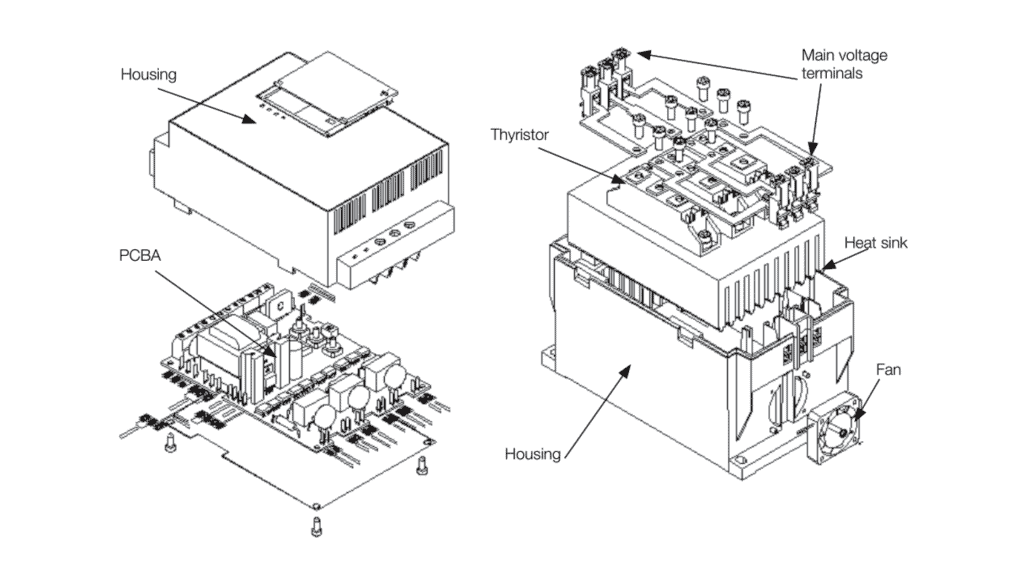

Soft starters may consist of mechanical and electrical devices or a combination of both. Mechanical soft starters include clutches and various sorts of couplings that transmit torque via fluid, magnetic forces, or steel shot, similar to other types of torque limiters. Electrical soft starters can be any control system that briefly reduces torque by lowering the voltage or current input, or a device that momentarily changes how the motor is linked in the electric circuit.

Soft Starter Working Principle

A motor soft starter works by adjusting the amount of voltage that flows through the motor’s circuits. This is accomplished by limiting torque in the motor and permitting the soft starter to progressively drop the voltage to allow for a smooth flow of current.

Specific soft starter models use solid-state devices to achieve precise levels of control. These devices are yet another way to regulate the amount of electrical current that flows through the motor allowing the soft starter to control the current in three discrete phases.

Most electrical soft starters have a series of silicon-controlled rectifiers (SCR) or thyristors to limit the voltage to a more controllable level when the motor begins to spin. These SCRs have an ON state to enable the flow of current and an OFF state to control and limit electrical current. The SCRs are activated when the machine is powered up. Additionally, they restrict the voltage and relax once the machine attains full power. This process drastically helps in reducing the heat of the motor and reduces overall mechanical strain.

Mechanical soft starts employ clutches and various couplings to limit the amount of torque in the motor by using fluids, steel shot, or magnetic forces. As previously explained, this reduces the voltage permitted to surge through the motor, allowing it to start up more softly and readily.

Applications of Soft Starters for Motors

1. Water or Liquid Pump Applications :

There is always a high risk of power surges associated with pump applications. In such cases, soft starters help in increasing the pressure gradually and reduce the associated risks.

2. Conveyor Belts

These systems used in industries move heavy loads and need to be optimized using a soft starter. The sudden starting of conveyor belts will probably lead to jerks, misalignment, unnecessary stress, and more to the belt drive components. Soft starters provide these belts with a smooth starting and stopping mechanism while protecting the belts.

3. Fans and Similar Systems

Large fans used in industries operate at a constant speed. They do, however, require starting protection such as Soft Starters to ensure smooth functioning and to keep them running for longer periods.

3. Motors using belts & pulleys:

The motor that drives a load via belts and pulleys cannot withstand the rapid jerks. It is attached to the load by a belt. For such motor applications, a soft starter provides a smooth start.

Advantages of Using Motor Soft Starters

Smooth Starting:

In contrast to typical motor starters, Soft Starters provide a progressive increase in voltage and consequently speed, resulting in a very smooth startup. There is no mechanical stress or jerks that could harm the motor.

Control Acceleration & Deceleration:

Soft Starters offer controls to accelerate and decelerate while starting the motor. This is influenced by the varying firing angle which is either quick or slow and is used widely in applications where startup acceleration is crucial. With such a significant advantage you can also determine the time to spend before powering up.

Zero Power Surges

The conventional motor starters allow maximum voltage to rush into the motor during startup. This results in a huge inrush current flowing into the motor causing circuit overload and a power surge in the motor. A soft starter protects the motor against mishaps by gradually increasing the voltage.

Multiple Startups:

Starting a motor requires a lot of energy. Few applications need the motor to power on and off numerous times within shorter periods. Depending on the machinery, conventional soft starters might not be able to power up or even face overheating issues due to the high starting current.

Using a soft starter can help in increasing the number of startups within shorter time periods without having to incur damage to the motor or the circuit.

Reduction of Overheating

During power-up, the initial blast with conventional starters is greatly reduced by soft starters. It does this by allowing a gradual voltage supply during startup This prevents the motor from overheating and shutting down temporarily while increasing the life span and durability of the motors.

Enhanced Operational Efficiency

Conventional Motor starters can cause problems such as motor overheating, malfunctioning, power surges, and more due to a full voltage supply regularly. A Soft Starter, however, can drastically reduce the associated risks and ensure the smooth functioning of machinery for multiple applications. The maintenance needs are also reduced because of lesser mechanical faults. The availability of devices at all times will greatly contribute to the increase in overall productivity and efficiency.

Extended Life Span

Soft Starter has many advantages when compared with conventional starters. The most important ones are enabling smooth operations, zero electrical and mechanical stress, zero power surges, multiple smooth startups, and more. All these will reduce the chances of damage to machinery in turn allowing the motors to function longer.

ABB Soft Starters

Are you a Consultant, OEM, Panel Builder, or End-user? ABB Soft Starters will add to your business value by securing motor reliability, improving installation efficiency, and increasing application productivity.

ABB’s soft starters protect motors from electrical stresses and extend their lifespans. They do so by allowing you to customize starting currents, which put a strain on the machine with conventional starting methods.

Over ten motor protection features are included to keep your motor safe from different load and network irregularities while the starting currents are easily optimized to your load, application, and motor size.

Your motor is secure in the hands of your machine, thanks to many built-in protection systems. Soft starters from ABB are also easy to install and use, lowering installation time as well as decreasing assembly and startup time.

A single Softstarter contains all of the features needed to start a motor, from bypass contactors to overload protection, making it compact and efficient. Furthermore, ABB’s soft starters will assist you in increasing production by providing various application-specific functions. Extra features such as torque control, pump cleaning, and more will allow you to do more than soft starting.

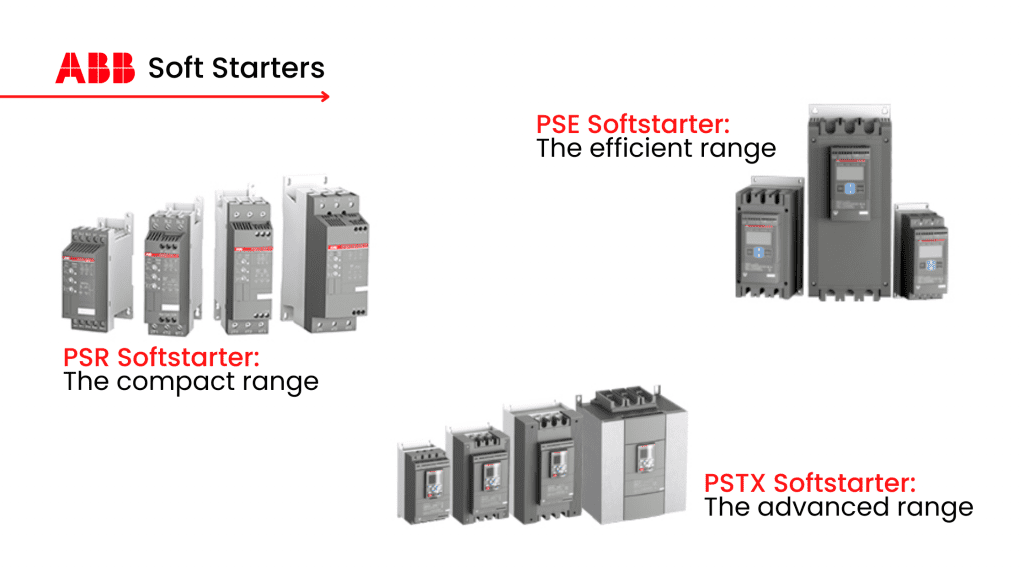

ABB Soft Starter Types

ABB Softstarters come in three types

- PSR Softstarter – the compact range

- PSE Softstarter – the efficient range

- PSTX Softstarter – the advanced range

PSR Softstarter – the compact range features

- Rated operational current: 3 to 105 A

- Operational voltage: 208–600 V AC

- Control supply voltage: 24 V AC/DC or 100–240 V AC

PSE Softstarter – the efficient range of features

- Rated operational current: 18 to 370 A

- Operational voltage: 208–600 V AC

- Control supply voltage: 100–250 V AC

PSTX Softstarter – the advanced range features

- Three-phase controlled

- Operational voltage: 208-690 V AC

- Wide-rated control supply voltage: 100-250 V, 50/60 Hz

- Rated operational current: 30…1250 A (inside delta: 2160 A)

- Coated circuit boards

- Torque control for excellent control of pumps

Features of ABB Soft Starters

- They cover motor applications from 3 A to 1250 A

- Quick and easy to install and setup

- Detachable keypad rated IP66 (Type 1, 4X,12)

- Built-in bypass for energy saving and easy installation

- Graphical display with 17 languages for easy setup and operation

- Built-in Modbus RTU for monitoring and control

- Coated PCB to protect from dust, moist and corrosive atmosphere.

- Torque control functions the absolutely best possible stop of pumps without water hammering and pressure surges.

- Softstarter programming software is free.

Micronova Impex is a one-stop solution for industrial electrical components. We are also India’s trusted and best online electrical e-commerce store. From us, you can buy ABB Soft Starters at the best prices that suit your requirements. If you’re finding difficulty in product selection, reach us at +91 8147090154 or digitalsales@micronova.in

Comment (1)

What happened if ph sequence changed of soft starter